🔨 Elevate Your Woodworking Game!

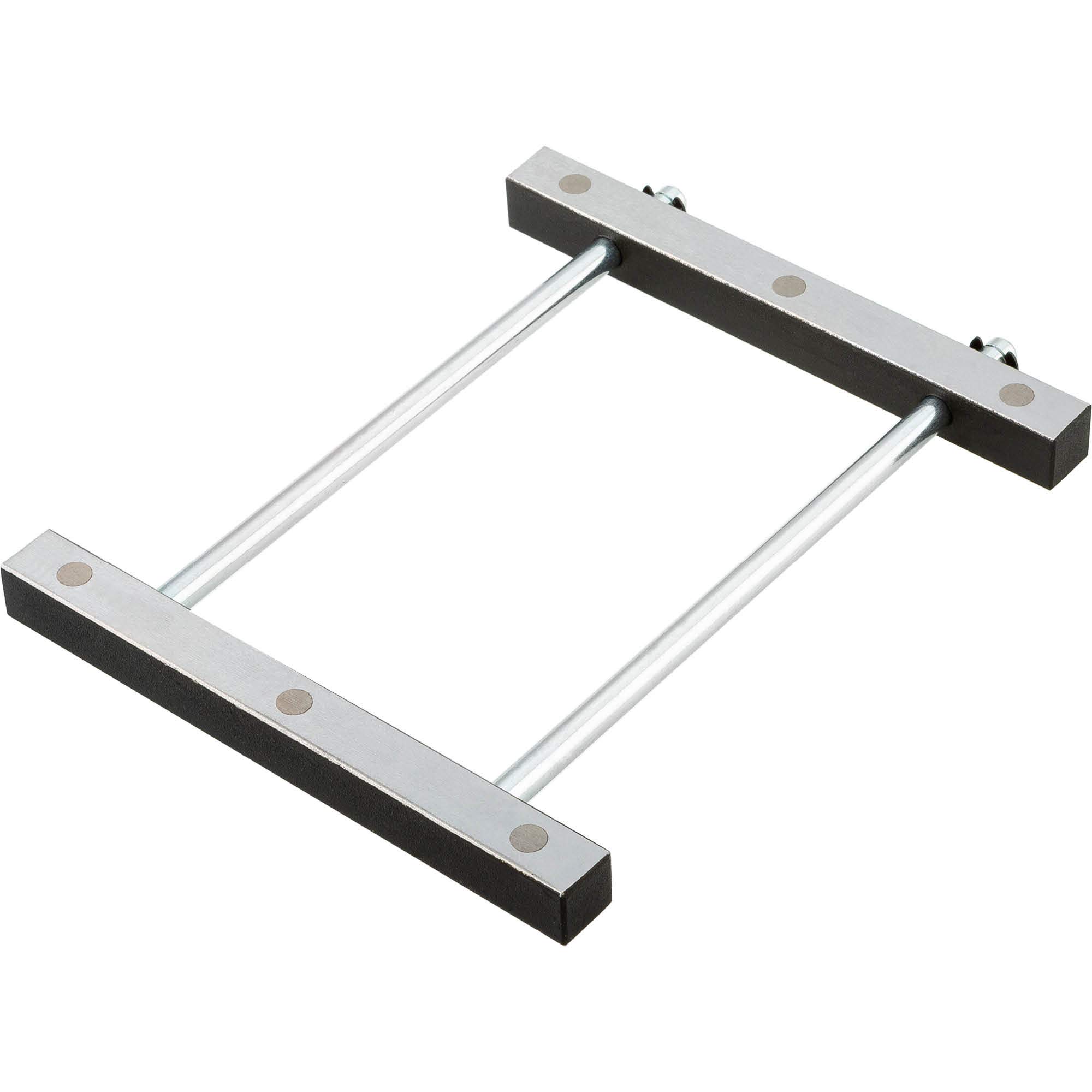

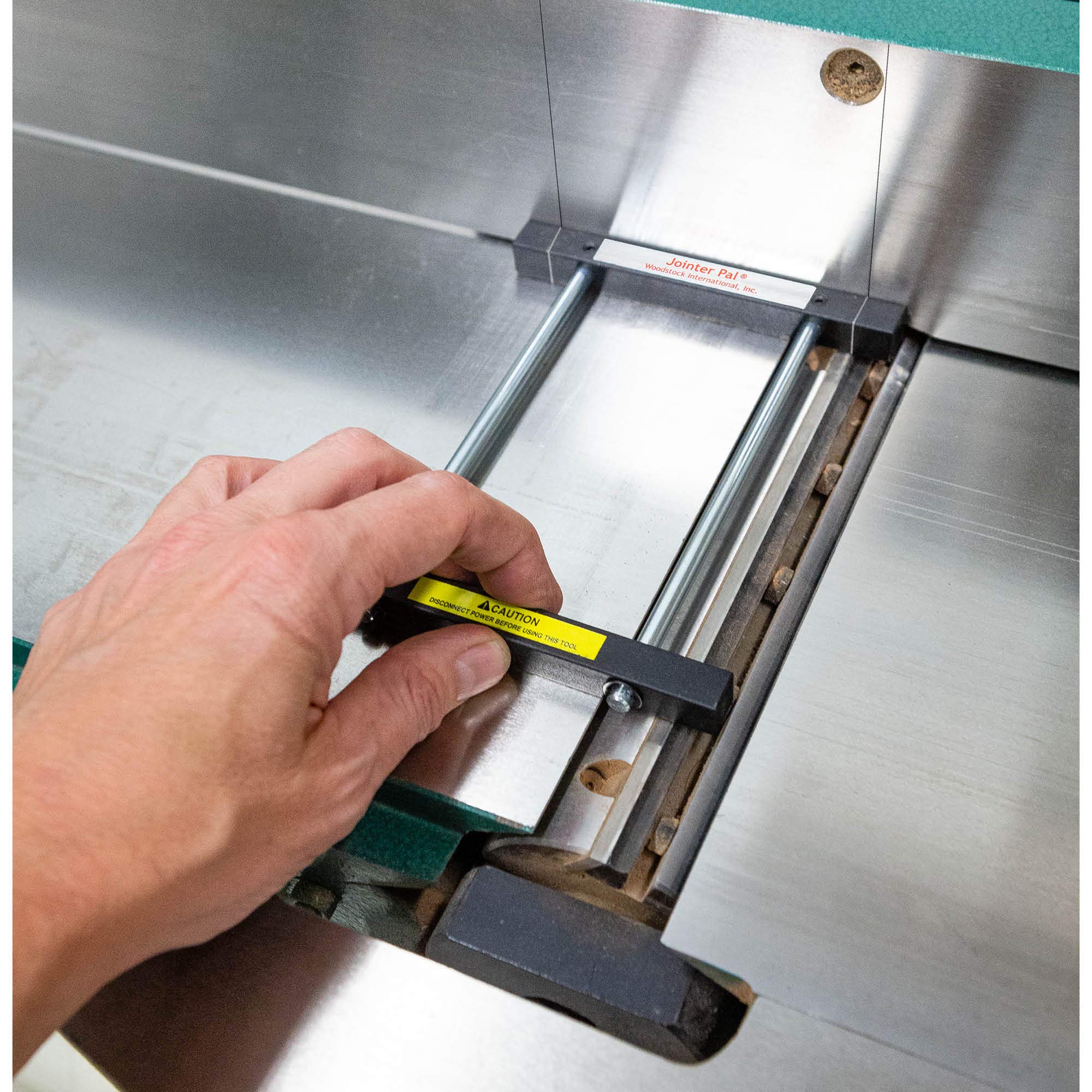

The Woodstock W1211A Jointer Pal Jig Standard is designed for 4 to 8-inch jointers equipped with high-speed steel (HSS) knives. Its robust steel body ensures durability while simplifying knife installation. With compact dimensions of 7.0" L x 6.25" W x 1.0" H and a lightweight design of just 15.5 ounces, this jig is the perfect addition to any woodworking toolkit, enhancing efficiency and precision.

| Manufacturer | WOODSTOCK |

| Part Number | W1211A |

| Item Weight | 15.5 ounces |

| Product Dimensions | 6.2 x 1.3 x 6.6 inches |

| Country of Origin | China |

| Item model number | W1211A |

| Is Discontinued By Manufacturer | No |

| Material | High Speed Steel |

| Item Package Quantity | 1 |

| Batteries Included? | No |

| Batteries Required? | No |

H**R

The jig WORKS - It's how you tighten the bolts that matters

THE JIG WORKS JUST FINE - GO SLOW WHEN TIGHTENING YOUR GIBSIT DEPENDS ON THE USER TO TIGHTEN GIBS PROPERLY - THE JIG DOES IT'S JOB OF HOLDING KNIVES JUST AS IT SHOULDJig got me set to within less than .001" cut height variation from knife to knife on my Delta 37-190 jointer - Did not achieve that tolerance the first time around but after removing and resetting knives again, I realized I'd gone too fast the first time aroundSLOW DOWN AND TAKE YOUR TIME, you can still be done in under 30 mins on a 3 knife cutter head - Wish the magnets were stronger, especially for the $30 price on this extremely simple tool but other than that it's great

A**R

Why would you use anything else?

These magnetic jointer knife installation tools are the way to go. Once you get the layout lines on your jointer and fence for the first time, the actual blade installation is about a 15 minute job. Use a scribe to mark the machine. Then you won’t have to remark ever. Unplug the machine. Take your time and measure carefully. The magnets make knife placement quick, accurate and repeatable. Don’t get distracted. After installation is complete, carefully recheck your work (all the bolts tight?) then enjoy the satisfaction of running a board over fresh, razor sharp blades. Well worth the effort. Several manufacturers make these tools. They look to be similar if not identical in design. Some are slightly more expensive and are made with more robust components. Avoid the plastic models if you can.Happy building🛠.

R**R

Works well

It works well.Works better than anything else I've used for setting jointer knives.First time set up is a pain. (Hence the rating)After TDC is marked it is a great deal easier.The magnets "kind of" hold the knives in place when you tighten the wedge nuts.I use a dial indicator on a magnetic base to find TDC to start and to check all the knives for consistent height at the end.

S**M

Is it really all that easy?

Really a very simple and easy to use jig. It requires a fairly straight forward initial set up but once you get it set up it allows you to align the jointer knives really quickly and even better than that, accurately.I bought a used Jointer with a three knife head and none of the knives where installed accurately. I tried to fix the situation, but decided to give this jig a shot after getting to the limits of just how accurate I could get things on my own. It took about 15 minutes to get it set up. Admittedly, I did fuss over it, checking and double checking for accuracy. Once I was satisfied with my set up it took me about 5 minutes to get all three blades aligned and tight. I then ran several pieces of wood through to check and I was very happy with just how nice of an edge it created.I definitely would recommend this jig. Just understand that the accuracy is in the initial set up. So be fussy.

R**A

Great jig, use a dial indicator to get TDC.

Find top dead center with a dial indicator. Use a combination square against the knife and resting on the top of the fence to scribe a line on the fence. Register the the line on the jig with the line on your fence. Scribe the second line on your fence from the jig (again using your combination square).The magnets worked well holding the knives after loosening the jib screws. Whole process took about 15 minutes. No snipe.There was a little oil on the magnet base that I had to clean up with mineral spirits.

A**R

Makes a tedious job easy!

After spending two hours trying to align the blades in mu Rigid 6" jointer and still not getting them right, I decided to try this jig. The unit is well made and easy to use. As some others mentioned, the alignment lines on the top and side weren't exact, but mine were a lot closer than some of the pics here., and definitely close enough to do the job. Spent about 10 minutes adjusting the blades and when I was done, the jointer cut perfectly! Well worth the money!

D**G

Gimmick

I bought one of these knife setting jigs because setting knives correctly on the jointer takes me about an hour each time and this time I thought I'd try something new. I guess the jig functions like they describe, it's just a couple of magnets with some flat steel bars. Here's the problem, to set knives you find Top Dead Center of the cutter head and usually make a mark on the fence. This is done with a trusty staight edge and combination square. Then you position your new knife in the cutter head and at this point I would use a straight edge to get one end of the knife roughly even with the outfeed table. Gently tighten one side of the knife and do the same with the opposite side. Now, with a dial gauge I would go back and fine tune the height of each blade making each ~.001 above the outfeed table. It took some time to get it right but the dial gauge doesn't lie.The problem with the jig is that I have to do all of these steps even using the jig. The only thing it helped with was roughing in the knives. When you tighten down the set screws knives tend to move a bit and this is still true when using the jig. Plus I always like to double check the knife height with the dial gauge to set each a bit high. You can buy yourself a dial indicator for less than $40 Grizzly G9849 Magnetic Base/Dial Indicator Combo - President's Special and get your jointer set just how you want it. Plus a dial indicator is useful aligning other shop tools.

G**N

Disapointment

Another reviewer said this was really needed, thus I got it. I wasted my money. I much prefer the adjustment tool that wcame with the planer as opposed to this. First, you have to attempt to find top dead center and mark it on the fence, then scribe the fence(I really did not want to scratch my nice new planer....). Finding exact TDC on an arc is not easy. In any case, after fiddling with it and ten checking the results with my gauge, it came out pretty sorry.I then reverted and used the gauge that came with the jointer and was able to adjust them all quickly and easily and they came out flat and the same. Thus, it now draws dust in the drawer... Anyone want to buy mine?

C**S

Simple jig that works

Having spent a frustrating day trying to set up my jointer blades evenly, by myself, I got the Jointer Pal and set it up. The jig is easy to use and accurate. Instead of the frustrating day, I spent a less frustrating 2 hours setting up my blades accurately. Most of the time was spent fiddling with the allen keys and getting the spacers in place properly. The jig looked after positioning the blades evenly at the proper height. The time I had spent fiddling with the blade height was reduced to a few minutes. This jig was a good investment.

R**N

Jointer blade setting jig.

Well made, works well and easy to use.

T**E

Excellent tool

Levelled the jointer knives with ease to the out-feed table. No fuss and a perfectly square work piece.

R**K

Decent

It is better than the straight edge method for setting jointer knives and cheaper than a helical head upgrade.

R**I

Affordable...well worth the price

Works great to reset jointer blades after sharpened or replaced.

Trustpilot

4 days ago

2 months ago