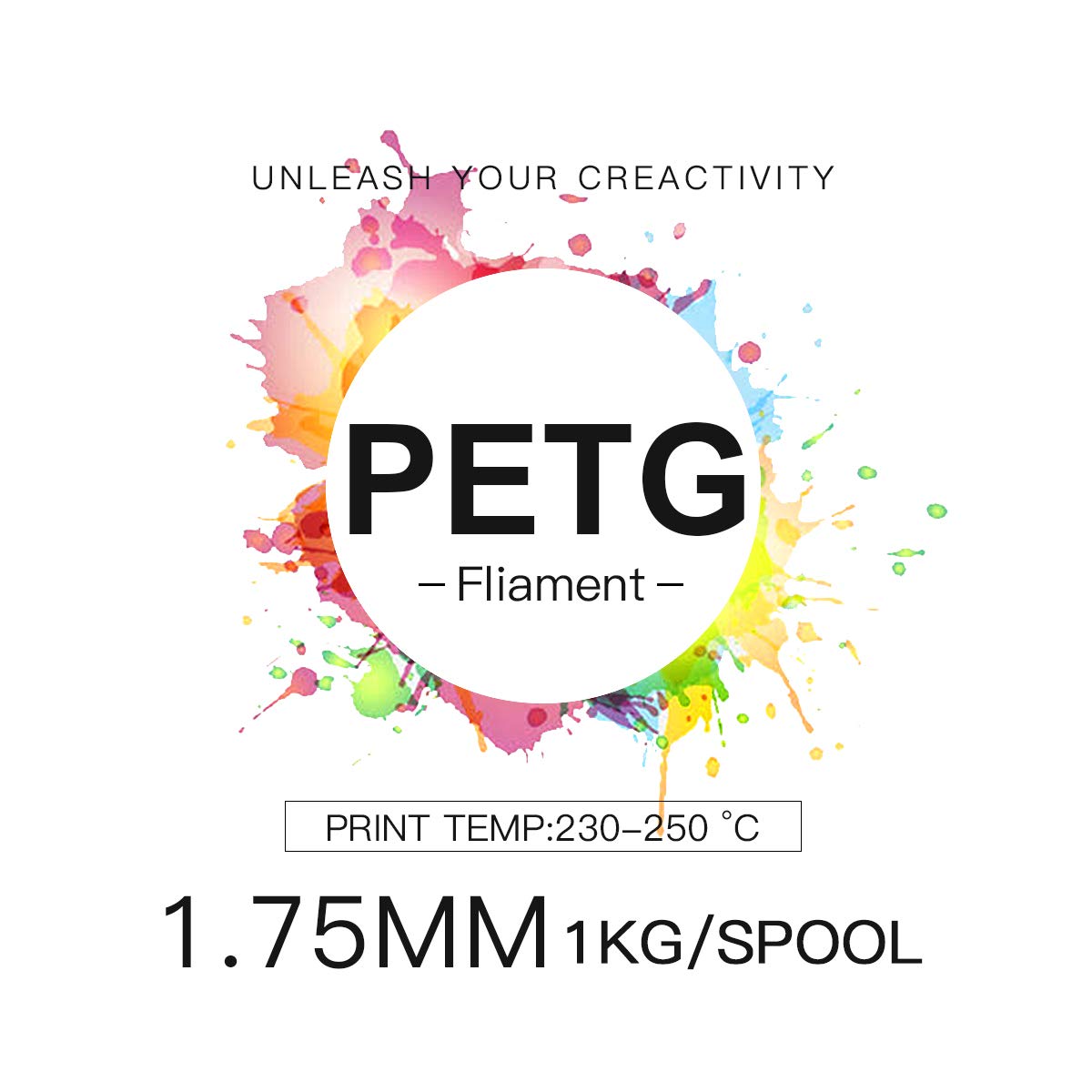

INLAND Micro Center PETG 3D Printer Filament 1.75mm - Green, 1kg Cardboard Spool (2.2 lbs), Dimensional Accuracy +/- 0.03mm

R**N

Not easy to tune (print settings included)

For average person who just bought a 3D printer for printing stuff off Thingiverse, GrabCAD, etc:If you just want to get filament that's easy to use, I recommend looking at HatchBox PLA, eSun PLA+/PLA Pro, Inland PLA, or any other PLA, these filaments are super forgiving and you can guess-timate the settings while still getting good prints.PETG is nowhere as easy to tune and requires printing at significantly slower speeds compared to PLA (For me, I'm printing PETG at 1/3 of the speed I normally print PLA)For people who actually need/want to use PETG:Definitely not the easiest thing to print, but the parts it produces are strong, flexible, and semi-transparent, not to mention this filament is pretty cheap.Pros:+Cheap ($18.99 per 1 Kg)+Strong (Took a lot more force to break a PETG part than the same part printed in PLA)+Consistent (my spool was 1.74mm throughout according to my Mituoyos)+Excellent layer adhesion (the aforementioned part actually split diagonally, cutting through layers and sections instead of splitting along a layer)Neither:+/-Semi-flexible (may or may not be a good thing depending on your application)+/-Spool is pretty average (just take a look at eSun's spools)+/-Zero tangles (this should be expected from any manufacturer, so its neither a pro or con)Cons:-Somewhat hard to Tune (applies to all PETG)Notes to help tuning: (my settings are below)-As counter intuitive as it is, turning off cooling actually helps reduce stringing-Higher temperature isn't always better-Small strings can be removed with a heat gun or hair dryer-Print VERY slowly-Stringing requires tuning the temperature in addition to the retraction distance and speedMy print settings: (MonoPrice Maker Select Plus/WanHao i3 Plus)Layer Height: 0.3Line Width: 0.39Printing Temperature: 235Bed Temperature: 80Flow: 100%Retraction Distance: 1.2mmRetraction Speed: 25mm/sPrint Speed: 35mm/sCooling: 0%

K**H

A totally different beast... but a good one. Learning required.

Totally different beast compared to PLA or ABS. Temperatures closer to ABS so you can make parts that won't melt in the sun as bad as PLA. And just tough as nails. Did a one mil cube test print and beat both my ABS and PLA filaments on strength.It's also the clearest material I've used. Other PLA's are translucent at best but this stuff is great for making things like a tail light cover that has a bulb behind it.Sticks great to bare glass, blue tape, the family cat. This stuff sticks great and doesn't warp very much. Now the bad news...it's like printing with bubble gum. Very, very stringy. .If you never played with "retractions settings" on your printer... well, you're about to. Those spider threads cool so fast and are so strong they can pull you print job off center or actually stop your print head. Difficult to control but can be done with a lot of trial and error. But it's all reusable knowledge you get.Chemical resistance is off the chart. I've soaked it in gas, acetone, naptha, xylene, paint thinner, alcohol, gun cleaner, brake cleaner and it's amazingly resistant. The one thing I've found that works for softening it to get a better final finish is dry cleaning fluid. The MSD sheet puts it in the mild to moderate range for human contact. Other things will work but unless your own the movie set for "The Andromeda Strain" you probably don't want to work with that stuff.One last tip... usually the better the print you want the slower you'll print the job. This stuff you want to print and keep that head moving at a good clip. Good fan control is essential. If your hot end lingers for a too long in any one area you'll get a big, melted glop right in the middle of your job so keep that hot end dancing at all times.

S**.

Good filament with some stringing issues.

If you cannot get a good print, try printing cooler.... (~220°c). The color looks great when that color is desired. Do not expect a translucent RED or a sharp PINK, it is neither, nor is it labeled as such. On the roll it looks more red (because of the black spool) so do not compared the printed part to filament on the roll.Took a while to figure out the best setting for this, FOR ME, i needed to actually bring my temp settings doooooooown. In order to maintain a good print with strong adhesion and minimal stringing 220°c works best for me through a .4mm-.6mm nozzle on a E3D v6 setup. I typically run around 40mm/s unless it is something that i do no need a lot of directional changes, like a vase, then i'll go up to 50-60mm/s. Fan is set around 20% as well, although the higher the setting the "prettier" the filament finish looks but you sacrifice some strentgh through minimal layer bonding . I wouldn't recommend going over 50% on fan speed. Remember it is a PET not PLA or ABS. Some rapid cooling is ok, you're not risking the warping like with an ABS but you'll still not want to spin it to fast, it'll cool before it has time to tighten down on the previous layer.Cons would be the stringing and ability to retract and flow rapidly. Thus, infill can be greatly effected so it requires bumping the infill percentage up. In the beginning I was not a fan of this filament until i finally figured out HOW it works best with MY set up. I kept trying to run it hot and i just couldn't get it to work.

Trustpilot

2 months ago

4 days ago